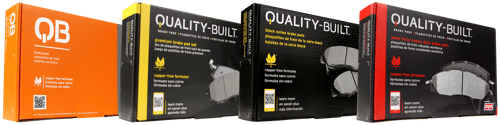

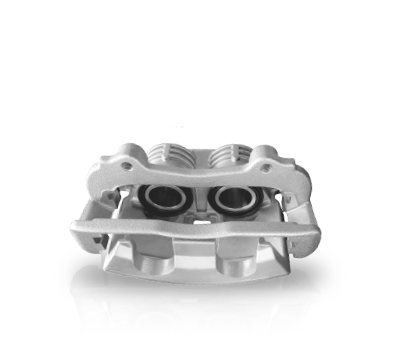

Motorcar Parts of America is proud to announce the addition of Quality-Built replacement brake pads and rotors to our extensive product portfolio. Backed by over fifty years of product innovation and engineering expertise, this full line of brake system components provides a wide range of application coverage and options for every type of driver and vehicle. Quality-Built brake pads are available in four formulations, each engineered for maximum performance and durability in any driving situation. Quality-Built brake rotors feature OE design and metallurgy to restore safe, confident braking for any vehicle.

QB Brake Pads by Quality-Built

QB Brake pads deliver like-new stopping power with minimal brake dust and noise.

Quality-Built Premium Brake Pads

Quality-Built Premium Brake Pads restore like-new stopping power.

Quality-Built Black Series Brake Pads

Enhanced friction formulations for improved performance & durability. The ultimate in performance and reliability.

Quality-Built Work Force Brake Pads

Hardworking vehicles need tough pads, and Quality-Built delivers every time.

QB Brake Pads provide a secure and reliable stopping power, ensuring your safety on the road, while keeping dust and noise to a minimum.

• Dependable stopping power

• Multi-layer shims

• OE style slots and chamfers

• Precision cut backing plates for hassle-free installation

• Post cured and scorched for easy bed-in

• Copper-free 2025-compliant formulations

• Part number sequence starts with 1000 prefix

Over 1700 SKUs for 99% light-duty VIO coverage

Quality-Built Premium Brake Pads provide optimized stopping power in all conditions. Application-specific pad formulas remove the guesswork from pad selection by providing friction compounds engineered to restore like-new stopping power for every vehicle.

• Application-specific friction material

• Low dust, low noise friction formulations

• Multi-layer shims

• OE design slots and chamfers

• Stainless steel hardware included as required

• Precision cut backing plates for hassle-free installation

• Post cured and scorched for easy bed-in

• Copper-free 2025 compliant formulations

• Part number sequence starts with 1001 prefix

Over 1900 SKUs for 99% light-duty VIO coverage

Black Series

Premium Brake Pads

Quality-Built Black Series Brake Pads are the ultimate in brake pad performance, delivering smooth, reliable stopping with zero noise and low dust. Black Series friction compounds are engineered for optimized brake system performance and improve stopping power.

• Application-specific friction material

• Enhanced friction formulations for improved performance & durability

• Ultra-low dust, low noise friction formulas

• Multi-layer shims

• OE design slots and chamfers

• OE-style stainless steel hardware where required

• Precision cut backing plates for hassle-free installation

• Post cured and scorched for easy bed-in

• Copper-free 2025 compliant formulations

• Part number sequence starts with 1003 prefix

Over 1800 SKUs for 99% light-duty VIO coverage

Hardworking vehicles need hardworking brake pads, and Quality-Built Work Force brake pads deliver every time. Specially formulated friction compounds are designed for high-heat situations that push brake pads to the limits.

• Long wearing friction formulas

• Multi-layer noise abatement shims

• OE design slots and chamfers

• Low rotor wear for extended braking life

• Stainless steel hardware included where required

• Precision cut backing plates for hassle-free installation

• Post cured and scorched for easy bed-in

• Perfect for high-heat, repeat stop situations

• HD vehicles, towing, fleet vehicles, off-road applications

• Copper-free 2025 compliant formulations

• Part number sequence starts with 1002 prefix

Over 500 SKU’s for complete coverage for fleet and towing applications

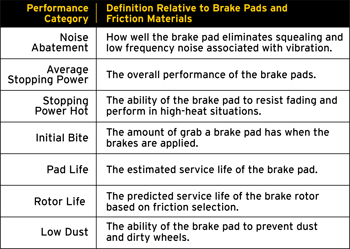

Understanding Radar Graphs

Radar graphs are a visual representation of a brake pads overall performance. Each attribute has a spoke with an associated value.

Higher values are farther from the center = Better Performance.

Lower numbers are closer to the center = Less Performance.

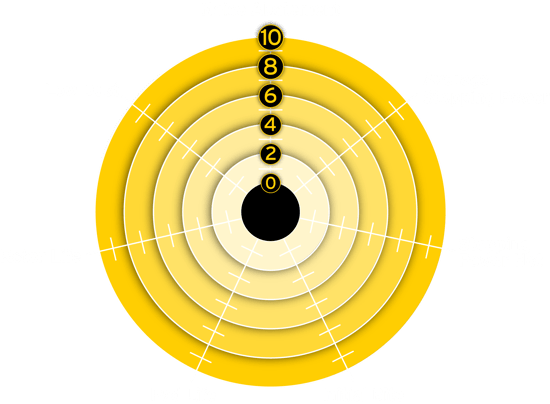

Copper-Free Friction Formulas

In 2010, the states of California and Washington enacted legislation that will require brake pads sold or installed in both states have reduced levels of copper and other heavy metals.

2015- Leaf A: The first level of the legislation began in 2014 in California and in 2015 in Washington. All brake manufacturers and importers were required to self-certify that their brake pads contained no more than 0.1% by weight of asbestos, cadmium, chromium, lead, and/or mercury.

2021 – Leaf B: On January 1, 2021, the second phase of the legislation went into effect. This phase required brake manufacturers and importers to self-certify that their brake pads contain no more than 5% by weight of copper.

2025 – Leaf N: The last level will go into effect in on January 1, 2025. Both states will require all brake manufacturers and importers to self-certify that their brake pads contain no more than 0.5% by weight of copper.

All Quality-Built Brake Pad formulations are manufactured in accordance with this legislation.

Powered By MPA

We Are Motorcar Parts of America

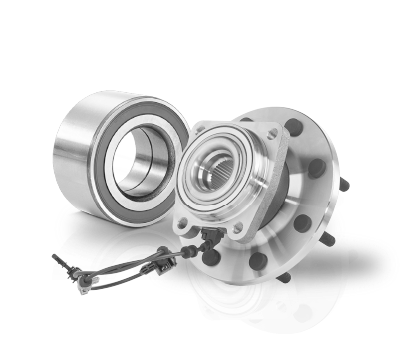

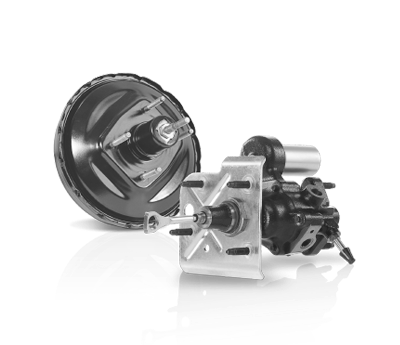

Powered by over 50 years of product innovation, manufacturing improvements and progressive ideas, MPA has positioned itself at the forefront of future transportation technology and global resource allocation. This passion for greatness and attention to quality has established MPA as the leading supplier of aftermarket replacement starters, alternators, hubs, and brake system components, all backed by cutting edge engineering, marketing support, training programs, and award-winning technical support.

Cultivate and grow your business together with us

With our unique way of presenting content and designs, MPA's Innovation Studio can help you reach your potential customers through many different social media plans, landing pages, and HTML email campaigns.

At MPA's Innovation Studio, we gather detailed consumer reports and data during a comprehensive research approach with detailed analytics to ensure your brand gains proper attention with the appropriate web presence.

.webp?width=1241&height=760&name=pbmpa-logo%20(1).webp)

.png?width=1230&height=466&name=QB_Lockup_2020Update_CM%20100523%20(1).png)